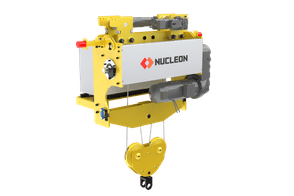

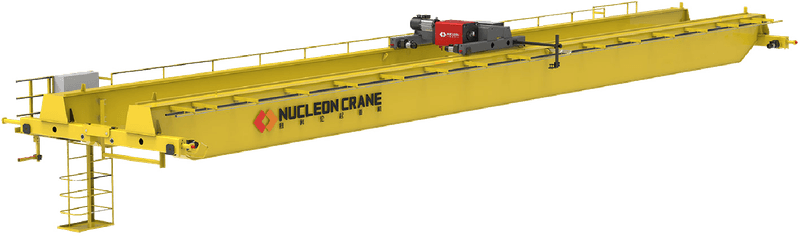

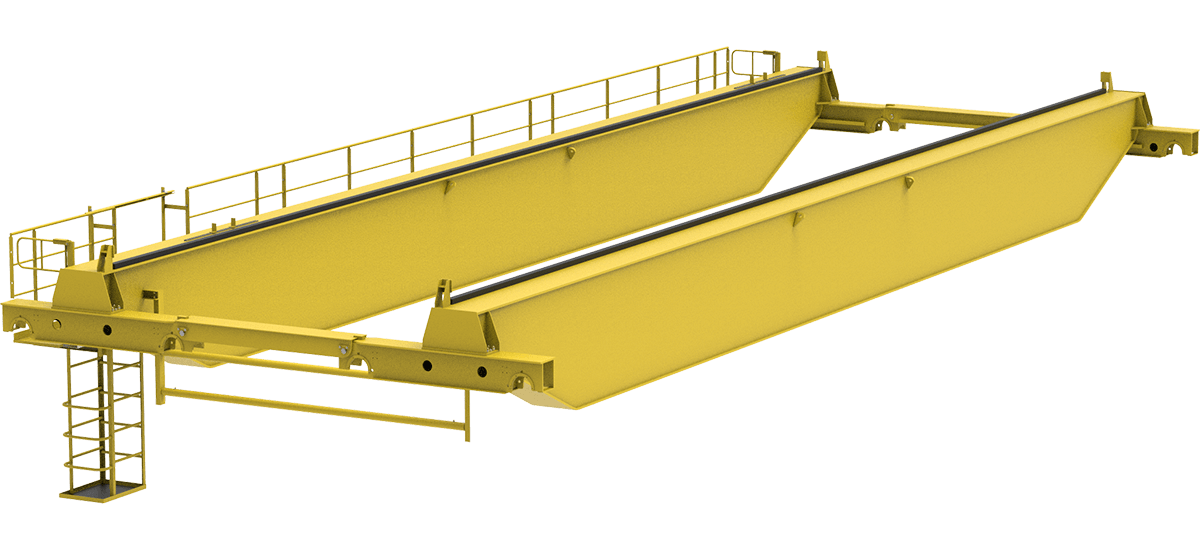

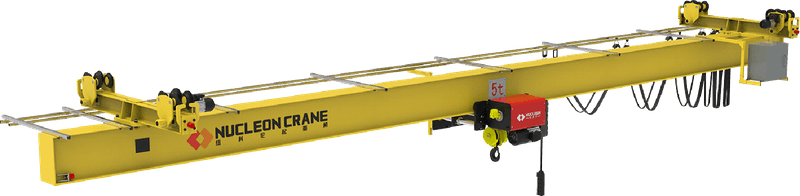

Lightweight Structure Design

- High-strength square steel rails instead of P-type rails, changed from pressing clips to welding clips

- The bridge frame adopts a box-type four-beam structure

- The size of the steel structure is reduced under the premise of satisfying the stiffness and strength

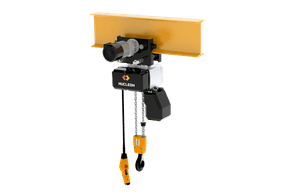

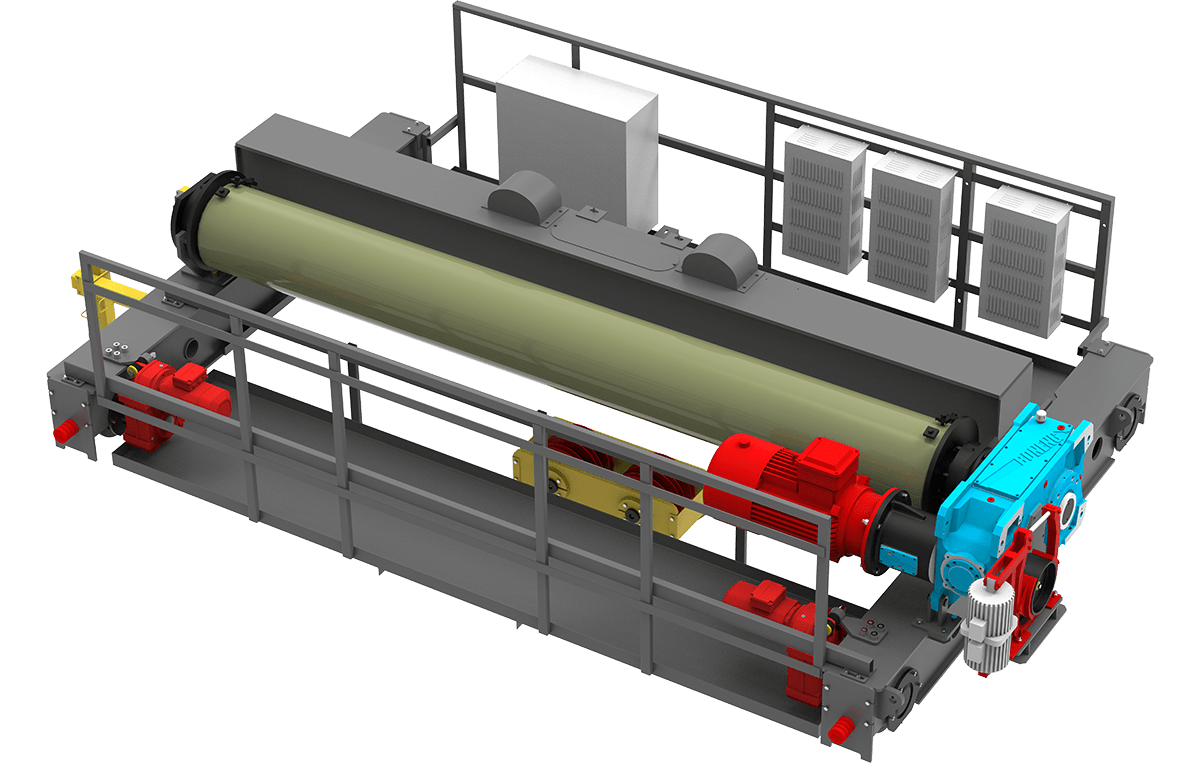

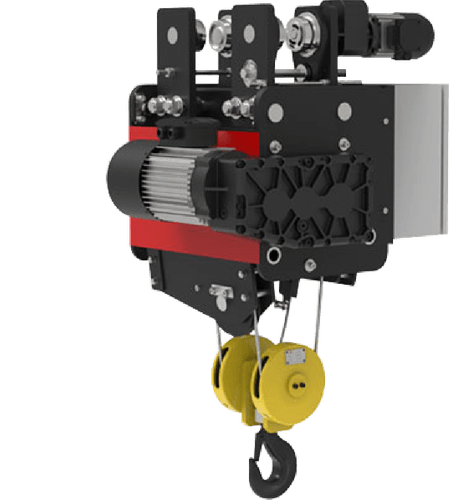

Lightweight Trolley Design

- High-efficiency variable frequency motor

- Hard-toothed mute reducer; High-strength wheel set

- Both single wheel structure and boogie structure to meet different wheel pressure requirement

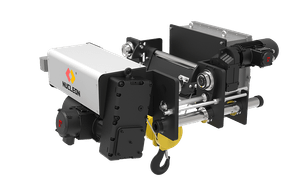

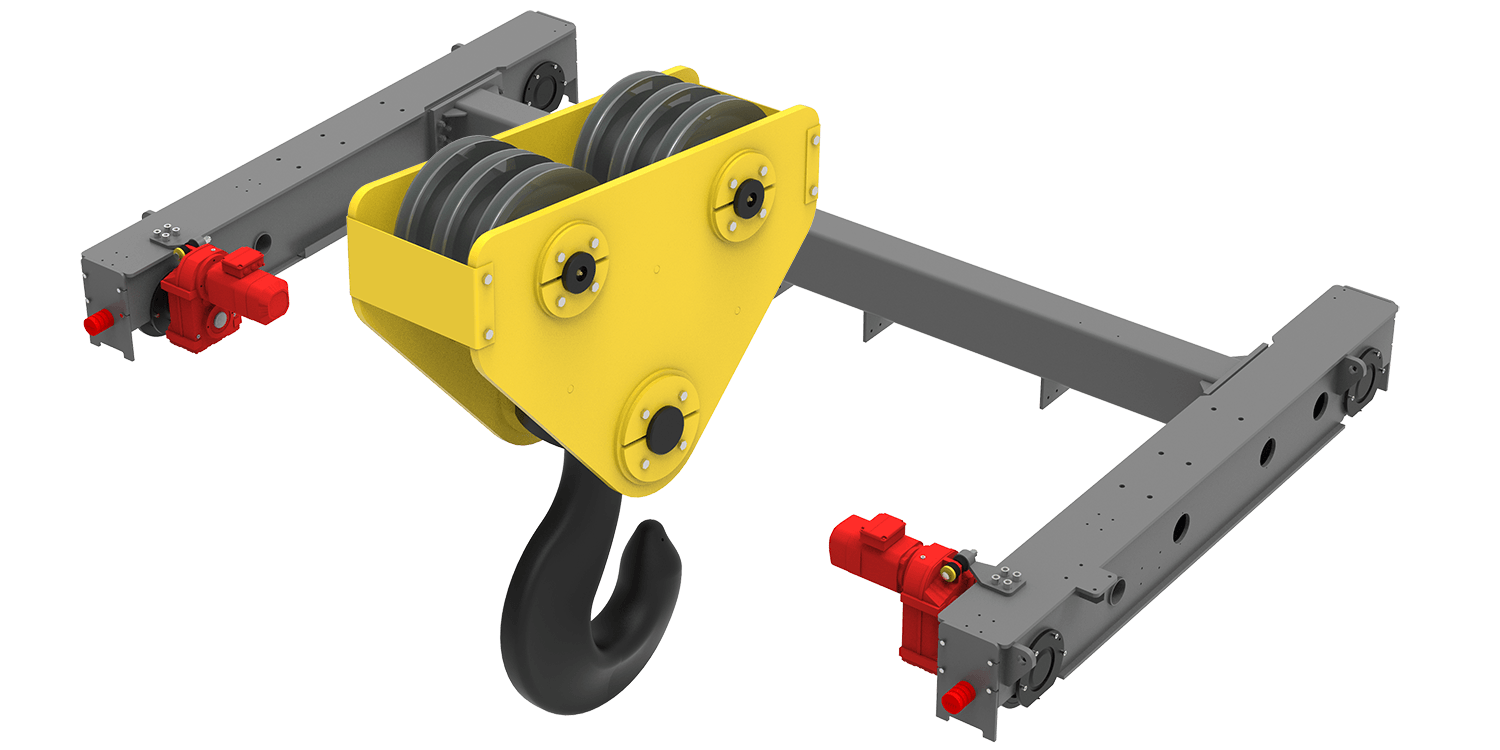

Lightweight Traveling Mechanism

- High-strength galvanized steel wire rope

- Rolled or high-strength nylon pulley block

- High-strength hook set

- H-shaped three-beam structure composed of one horizontal beam and two longitudinal beams

INTELLIGENT CONTROL

Crane Load Sway Amplitude: Reduced By Over 95%Sway Angle: Less Than 2‰ Radian

Big Data Communication

Anti-swing

Anti Skewed AndInclined Lifting

Real-timeMonitoring

Loginc Control

Travelling Record

Overload Protection

Voltage AndCurrent Protection

Fault InformationDisplay

SMART SECURITY MONITOR

Increase Efficiency, Productivity, And Safety In Crane Operations.

- Real-time monitoring and recording of operational data

- Safe remaining duty cycly(SWP%)

- Brake safety remaining duty cycle(BrSWP%)

- Accumulated hoisting motor start times

- Overload protection and alarm

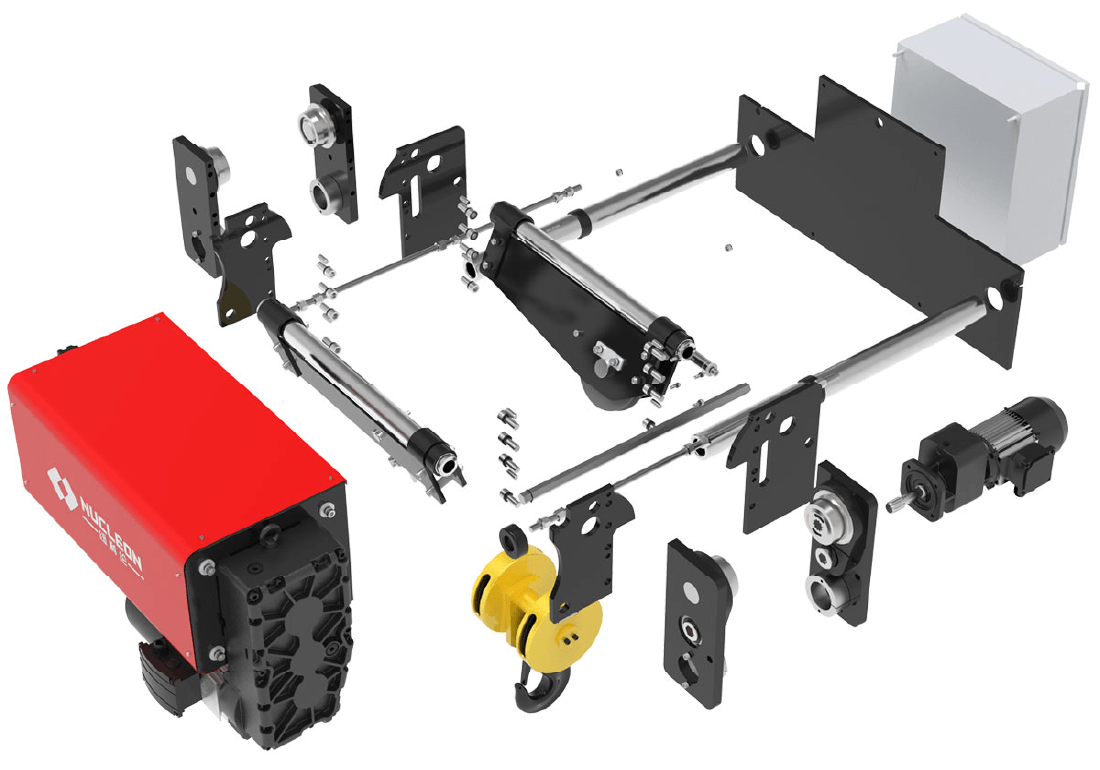

MODULAR STRUCTURE

Greater Flexibility, Improved Product Quality, And Lower Costs.

The modular structure is to form various products through different combinations of some basic modular units, which has met the requirements of users of other brands.

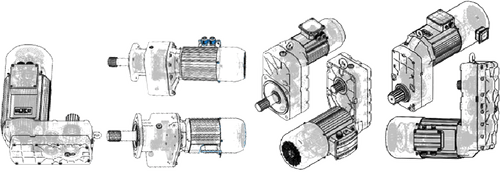

8 kinds of driving devices can match 15 kinds of motor power.

Experience The Power Of Our Factory In Virtual Reality

430,000 Square Meters, More Than 3,000 Sets Of Equipment

SERVING GLOBAL CLIENTS

Your Satisfaction Is Our Priority

- Provide technical consultation and customize design solutions for free.

- 130-engineer scientific research team, 5 powerful R&D platforms.

- Construction drawings can be automatically generated from quotation, scheme design to exwork.

- Provide technical consultation, technical training and answer other product-related questions

- Guide you through the installation of lifting equipment.

100+

Countries On 5 Continents+100,000

Sold Cranes1500+

Employees7*24h

After-sales Service

New-design Bridge Cranes

Lightweight, modular and parametric design.

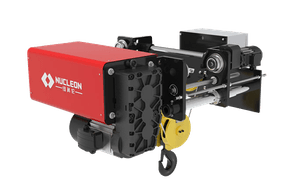

Hoisting mechanism uses NR model steel rope electric hoist with superior performance and advanced technology.

Traveling mechanism of trolley is driven by three-in-one drive device

Zero Speed Hover

Ensure that the crane moves slowly and accurately as it approaches its destination.

Multi-hook Coordination

Monitor and control position difference of multiple hooks to make the hooks run synchronously at the same speed.

Multi-trolley Synchronization

Position difference of multiple cranes can be monitored and controlled to make the crane operating mechanism run synchronously at the same speed.