Temos o prazer de anunciar o envio bem-sucedido de um guindaste semi-pórtico personalizado de 3 toneladas, estilo europeu, para um cliente na Tunísia. Este projeto exemplifica nosso compromisso em fornecer soluções de elevação personalizadas que atendam a necessidades operacionais específicas.

Histórico do Projeto

O cliente precisava de um sistema de elevação compacto, porém eficiente, para suas instalações, que tinham restrições espaciais e exigiam alta precisão no manuseio de materiais. Um guindaste semi-pórtico foi identificado como a solução ideal, oferecendo as capacidades de elevação necessárias e acomodando-se ao layout da instalação.

Desafios do Projeto

- Restrições espaciais: O espaço limitado da instalação exigiu um projeto de guindaste que pudesse operar efetivamente sem grandes modificações estruturais.

- Precisão e confiabilidade: as operações do cliente exigiam um sistema de guindaste que pudesse fornecer movimentos precisos e desempenho consistente.

- Integração de componentes de alta qualidade: garantir que o guindaste estivesse equipado com componentes confiáveis e duráveis para minimizar a manutenção e o tempo de inatividade.

Soluções

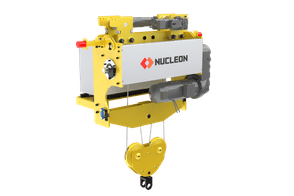

Para enfrentar esses desafios, fornecemos um guindaste semi-pórtico com as seguintes especificações:

- Carga de trabalho segura: 3 toneladas

- Vão: 8 metros

- Altura de elevação: 6 metros

- Classe de Trabalho: A5

- Velocidade de elevação: 0,8/5 m/min

- Velocidade de deslocamento transversal: 2–20 m/min

- Velocidade de deslocamento do guindaste: 3–30 m/min

- Fonte de alimentação: 380 V/50 Hz/trifásica

- Modo de controle: controle remoto

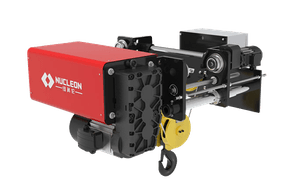

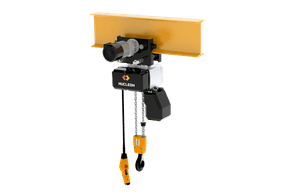

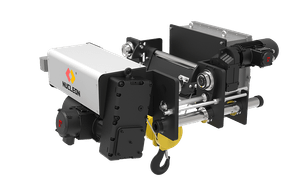

O guindaste é equipado com um guincho elétrico de cabo de aço de padrão europeu e um conjunto completo de componentes elétricos importados da ABB, garantindo alto desempenho e confiabilidade. Os motorredutores são fabricados internamente, permitindo controle de qualidade e personalização para atender aos requisitos específicos do cliente.

Visão geral do componente

- Talha elétrica de cabo de aço padrão europeu: proporciona operações de elevação suaves e precisas, adequada para aplicações que exigem alta precisão.

- Componentes elétricos ABB: reconhecidos por sua confiabilidade e eficiência, esses componentes contribuem para o desempenho geral e a segurança do sistema de guindaste.

- Redutores de motor fabricados internamente: projetados sob medida para atender às necessidades operacionais do guindaste, garantindo integração perfeita e desempenho ideal.

Entrega e Instalação

O guindaste foi cuidadosamente embalado e enviado para a Tunísia, com todos os componentes inspecionados para garantir que atendessem aos nossos padrões de qualidade. Na chegada, nossa equipe técnica forneceu orientação para a instalação, garantindo que o guindaste estivesse operacional dentro do cronograma projetado.

Feedback do cliente

O cliente expressou satisfação com o desempenho do guindaste, destacando sua precisão, confiabilidade e facilidade de operação. A integração de componentes de alta qualidade e o design personalizado contribuíram para melhorar a eficiência em seus processos de movimentação de materiais.

Para obter mais informações sobre nossas soluções de guindastes semi-pórticos ou para discutir suas necessidades específicas de elevação, entre em contato conosco.