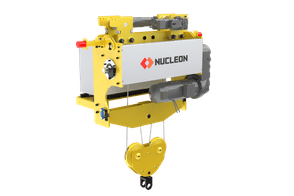

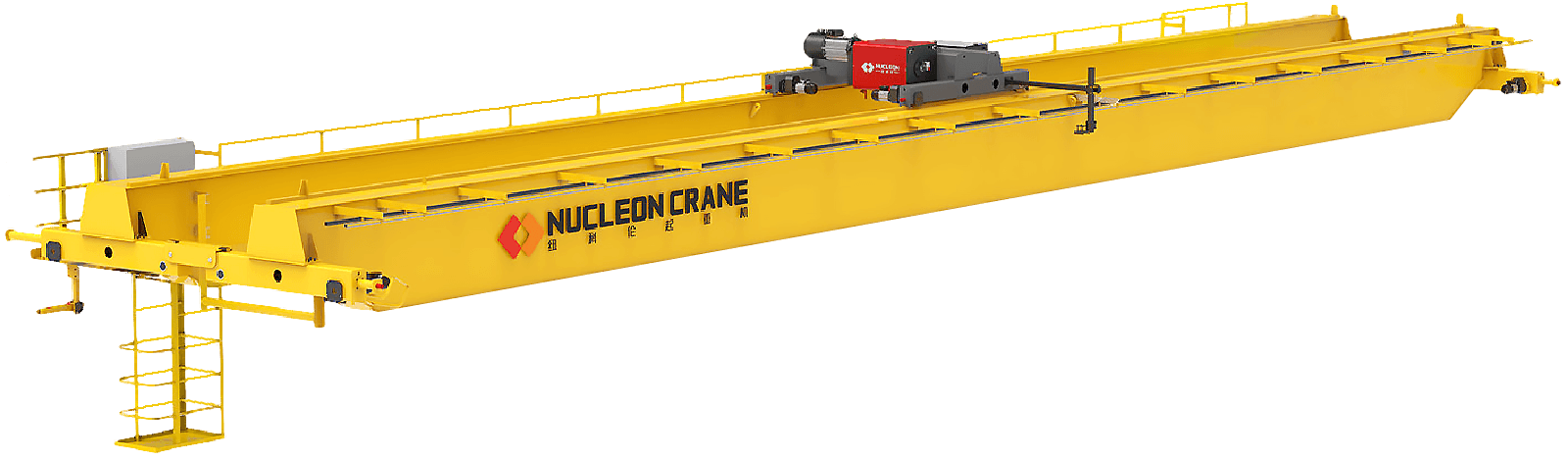

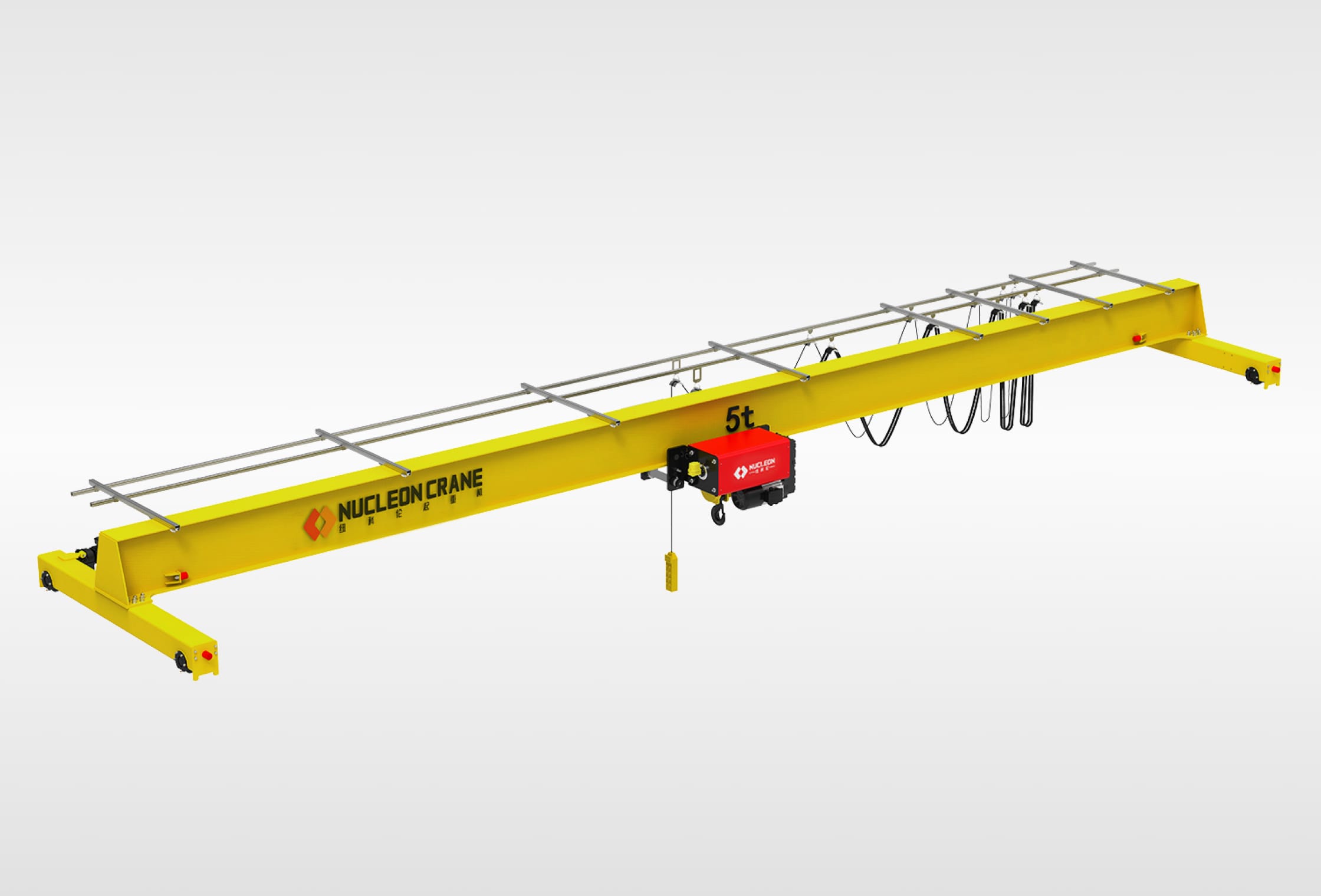

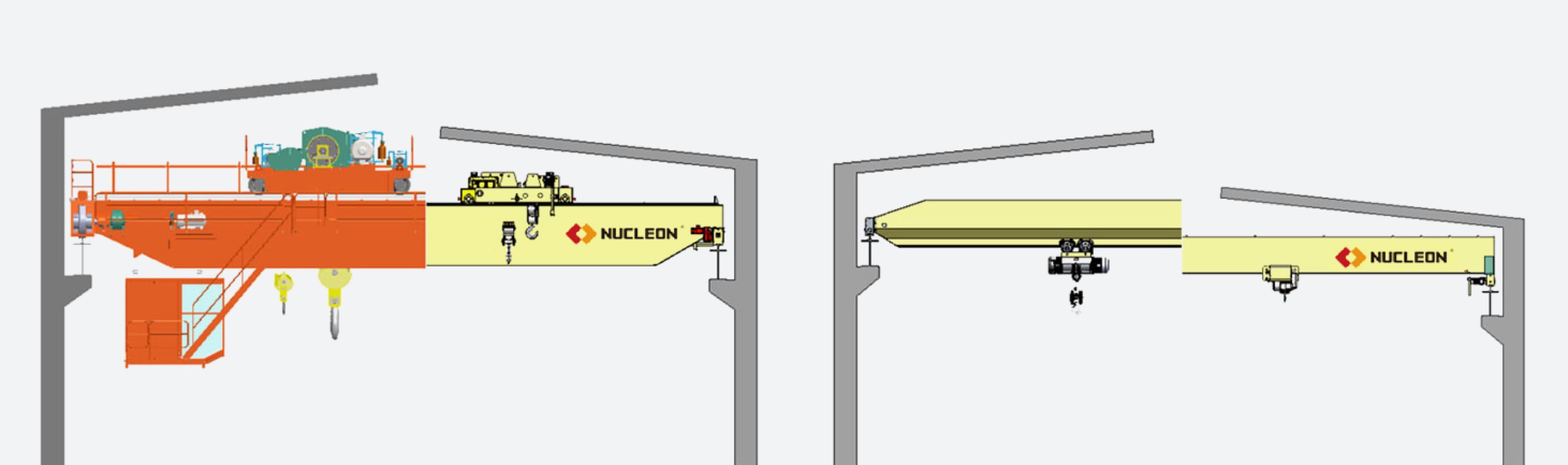

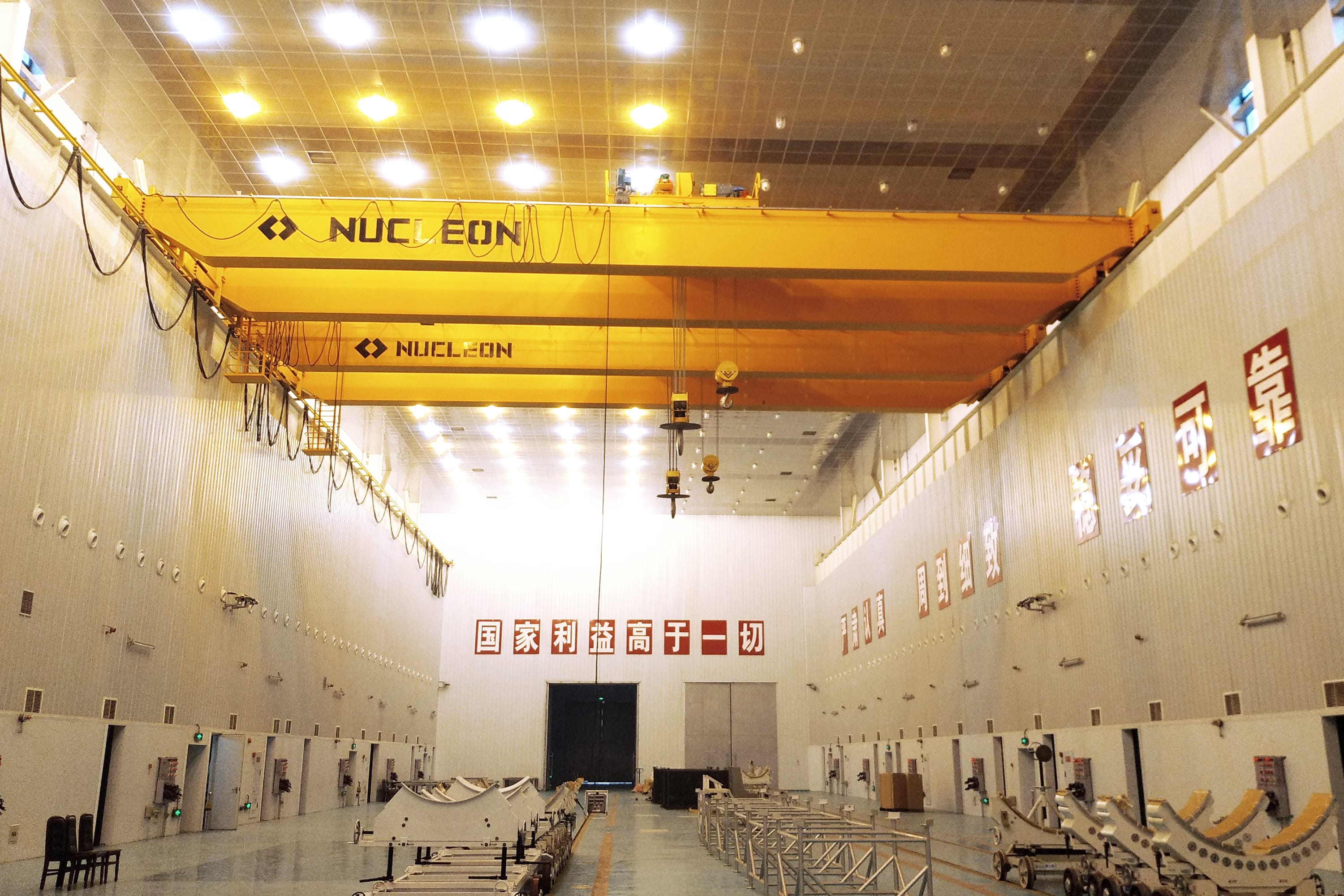

HD Single Girder Overhead Cranes

- 30% lower overall height: compact structure, reduced plant height needs

- 20% lower energy consumption: reduced electricity costs

- < 70 dB operating noise: improves workplace comfort and health

- 30% increase in torsional strength: integrated rectangular end beams

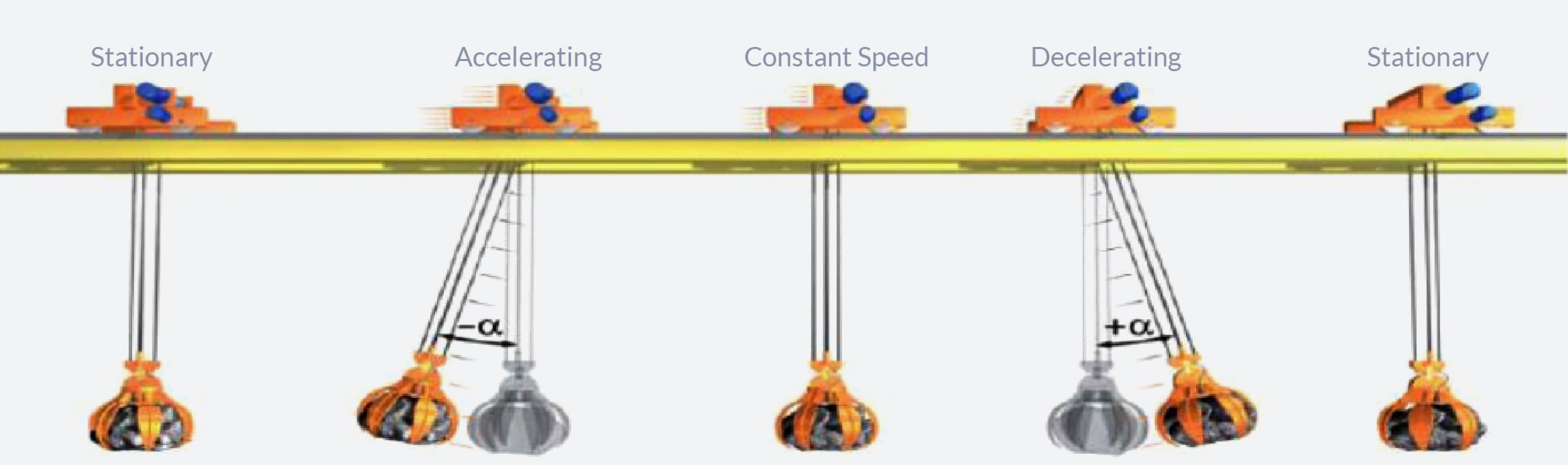

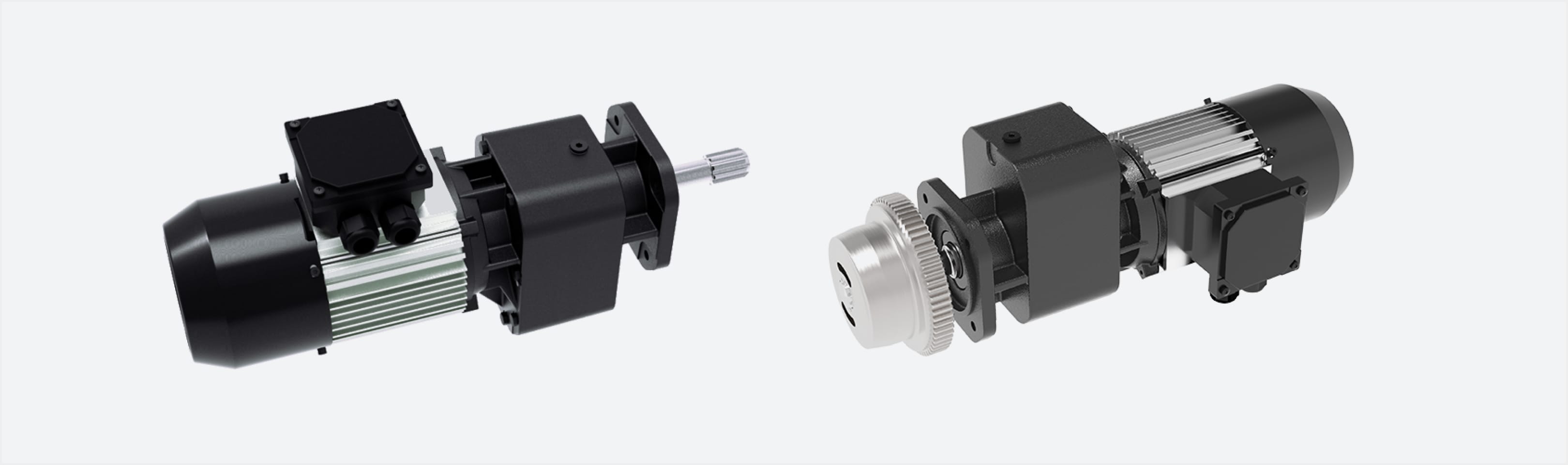

- 90% reduction in impact force: VFD-controlled integrated motor-reducer-brake system

- 2160 MPa wire rope breaking strength: 15% higher safety margin

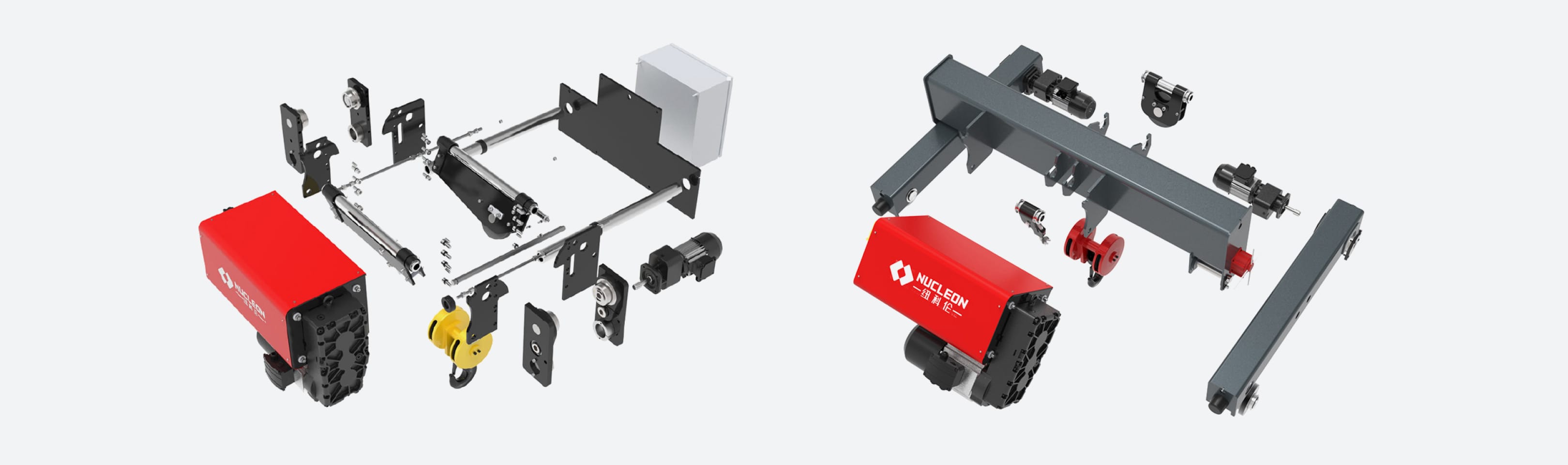

- 50% higher maintenance effciency: modular, interchangeable parts