5 tonns svingkran

Bygger og reparerer offshore lasteskip og slepebåter.

Bangladesh

Et mellomstort verft i Chittagong, Bangladesh – som spesialiserer seg på bygging og vedlikehold av offshore lasteskip og slepebåter – har nylig opplevd en kraftig økning i ordreinngangen. Imidlertid hindret de utdaterte løftesystemene og avhengigheten av manuelle operasjoner produksjonseffektiviteten. Som svar kontaktet verftet Nucleon for å utforske en mer avansert og robust materialhåndteringsløsning.

Viktige spesifikasjoner:

- Maksimal armlengde: 10 meter

- Lastekapasitet: 0,25 til 5 tonn

- Svingområde: 180°, 270° eller 360°

- Strømforsyning: 220–690 V, 50/60 Hz, 3-fase

- Kontrollalternativer: Anhengs- og trådløs fjernkontroll

Prosjektimplementering

- Evaluering av området: Vårt ingeniørteam utførte en detaljert undersøkelse av området for å ferdigstille installasjonsoppsett og tekniske parametere.

- Design og produksjon: Skreddersydde design ble utviklet, og produksjonen ble startet i henhold til strenge kvalitetsretningslinjer.

- Kvalitets- og sikkerhetstesting: Kranen gjennomgikk grundige inspeksjoner, inkludert lasttesting og verifisering av samsvar med internasjonale sikkerhetsstandarder.

- Sertifisering og forsendelse: Etter å ha mottatt alle nødvendige sertifiseringer, ble kranen forsvarlig pakket og sendt sjøveien.

Under den innledende konsultasjonen la Ratan, klientens prosjektleder, vekt på viktige krav: «Løftekapasiteten må ikke være mindre enn 4 tonn. Den skal være enkel å betjene, sikre høy sikkerhet og kunne tåle den harde, saltholdige luften under Bangladeshs monsunsesong.»

Med dette i betraktning arrangerte salgssjef Hani i Nucleon umiddelbart et tverrfaglig teammøte som involverte avdelingene for teknisk utvikling, ingeniørfag og ettersalgsservice. Gjennom en ekstern videokonferanse utførte vårt tekniske team en detaljert vurdering av driftsmiljøet, løftebehovene og korrosjonsutfordringene spesifikt for verftets kystnære beliggenhet.

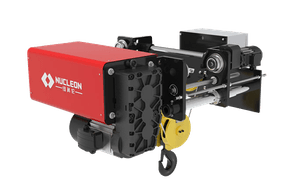

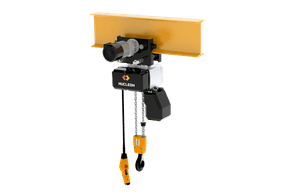

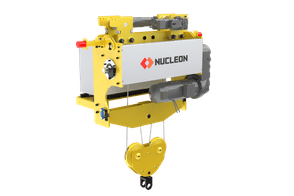

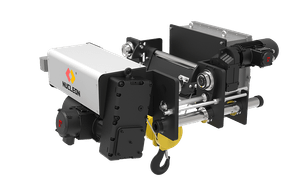

Basert på analysen vår foreslo vi en 5-tonns svingkran, et steg opp fra kundens opprinnelige forventninger. Den tilpassede løsningen ble ferdigstilt i løpet av en uke og ble designet for overlegen lasteytelse, intuitiv kontroll og langvarig holdbarhet i korrosive miljøer.

Ved ankomst til havnen i Bangladesh ble Nucleons tekniske team sendt ut for installasjon og igangkjøring på stedet. Vi ga også praktisk opplæring til verftets driftspersonell for å sikre sikker og effektiv kranbruk fra dag én. Kunden rapporterte en betydelig økning i driftseffektiviteten siden utplasseringen. De fremhevet kranens stabilitet, brukervennlighet og Nucleons responsive service. Ratan uttrykte stor tilfredshet og en vilje til å forfølge fremtidige samarbeid med Nucleon.

Dette vellykkede prosjektet demonstrerer Nucleons evne til å levere skreddersydde kranløsninger med høy ytelse, skreddersydd for utfordrende miljøer. Fra teknisk rådgivning til støtte etter installasjon har vår forpliktelse til kvalitet og profesjonalitet nok en gang vunnet kundenes tillit – denne gangen ved de travle havnene i Chittagong.